Final embedded architecture example

Final embedded architecture example

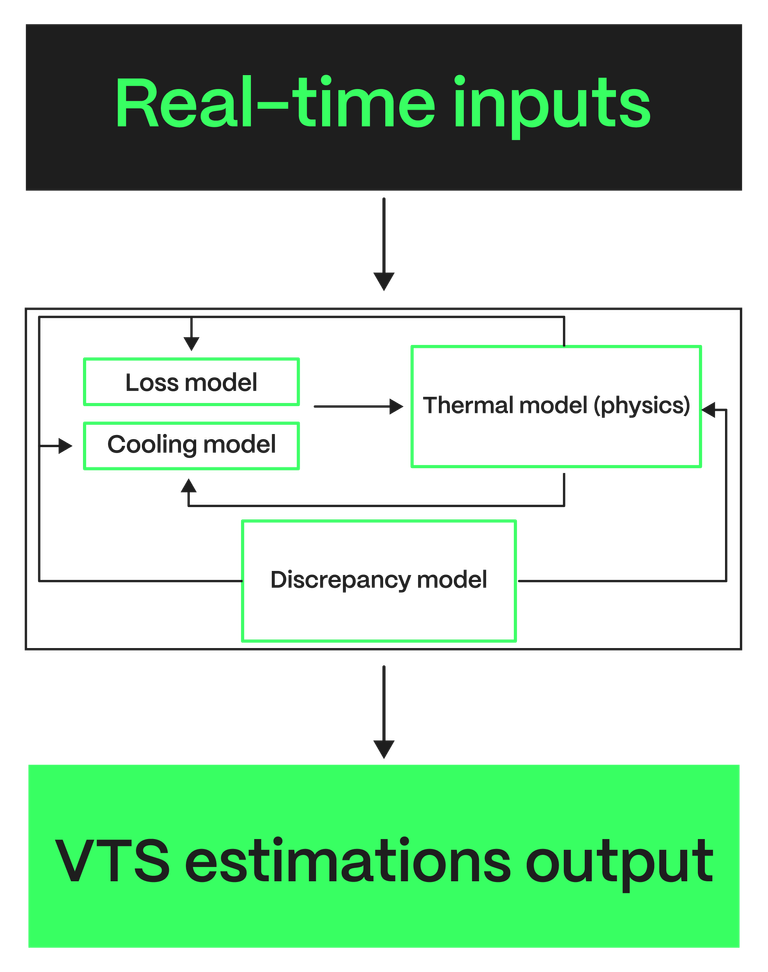

Our technology enables users to place Virtual Thermal Sensors anywhere within the component.

Benefits:

1. Full control over sensor placement in spots in which it is physically impossible to place a sensor in production: add, remove, or reposition virtual sensors with a few clicks.

2. Detailed temperature tracking for enhanced analysis of the system's performance.

3. Real-time monitoring of critical temperature hotspots that define the component's current derating strategy.

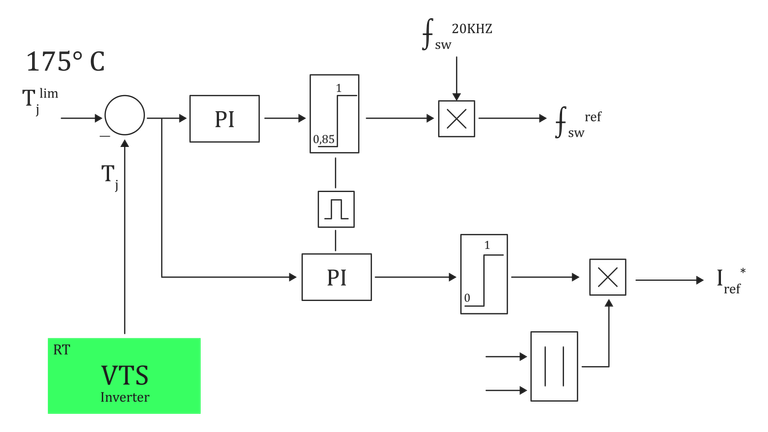

Example on power electronics

Example on power electronics

VTS

Real-time max junction temperature estimation

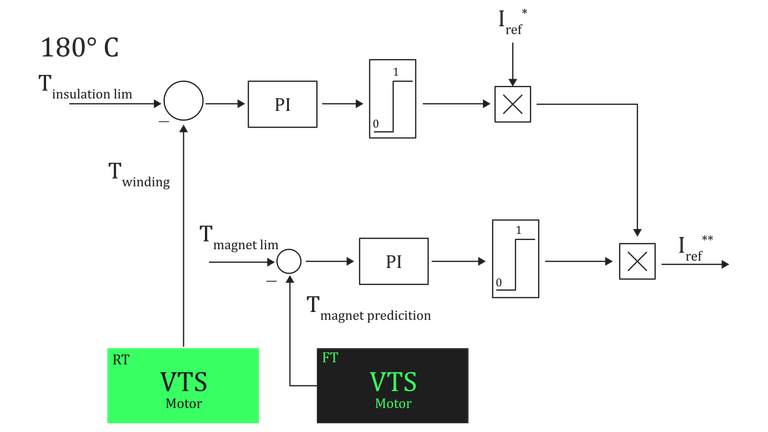

Example on motor control

Example on motor control

VTS

The max insulation temperature is calculated in real-time with high accuracy. The granular magnet temperature is predicted 100x faster than real-time